Am I Exposed Enough? Cold Spots (Blank Offs)

Neptronic electric heaters are equipped with automatic and manual thermal cutouts. The manual cutout is located between the control panel and the heating elements. Thermal cutouts are used to shut off the heater when temperature gets too hot as per UL/CSA/ETL (cutoff temperature varies with type of element). It is crucial to have them fully exposed to the airstream. Blocking air or having insufficient air near/around these thermal cutouts will cause the temperature to rise significantly and shut off the heater.

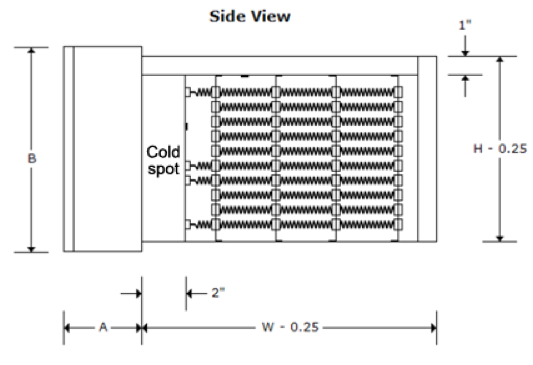

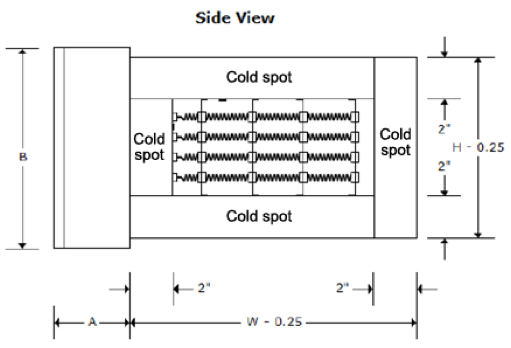

Cold spots are metal sheet add-ons that extend the distance between the control panel and the thermal cutouts (and coil) while keeping the same overall inside duct dimensions. This will expose the cutouts to the airstream.

For example, when a heater must be installed in an air handler that has a larger wall thickness, a cold spot on the control panel (box side) is recommended to prevent the manual thermal cutout and part of the coil from being blocked from the airstream and overheat.

Another situation where cold spots can be used is in installations where the air velocity is lower than the minimum velocity required for the PID switch (300 FPM) or Electronic Airflow Sensors (EAS) (100 FPM). In this situation, cold spots are a good solution, which can reduce the area through which the airstream passes and increase the velocity to make the PID and EAS while making sure the thermal cutouts and coil are fully exposed.

These cold spots can be used on all four sides of the heater (box, end, top, bottom) based on what is required, but it is highly important to make this request at the ordering stage. Modifications cannot be done to add cold spots once heaters are built.

To learn more about cold spots and electric heaters, visit our website.