Resistive vs. Electrode Humidifiers

Weighing the Pros and Cons

When selecting an electric steam humidifier for either a residential or commercial/industrial application, one of the first choices you are likely to face will be whether to

opt for a resistive or electrode humidifier. Each type is notably different in 3 main categories of efficient steam production:

- Heating water in order to produce the desired steam;

- Controlling steam output, and

- Maintenance requirements

In part one of this article, we will begin the exploration of these differences with a brief overview and quick explanation of controlling steam

output of electrode and resistive steam humidifiers.

Principles of Operation:

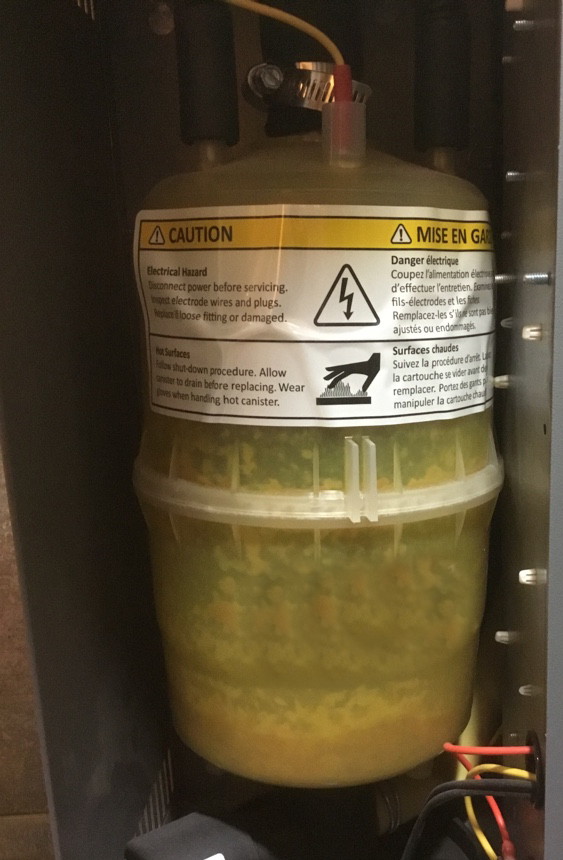

Electrode steam humidifiers bring water to a boiling point by passing an alternating current between electrodes within a disposable plastic

cylinder (the defining feature) utilizing the ions dissolved in the water as the means of conduction. Potable water (which contains dissolved ions) will conduct

electricity between the electrodes with substantial resistance, it will heat the water until the boiling point is reached and steam is produced. The capacity

of the unit will depend on the size of the cylinder (volume of water), the surface area of the electrodes in contact with the water and the rated voltage and

kW of the humidifier. A current transformer is used to monitor the current draw of the electrodes. It is the means of controlling the steam output which is

accomplished by raising or lowering the water level inside the cylinder. As the cylinder fills with water, more of the electrode surfaces will be immersed

allowing more current to pass between them thereby increasing the power consumed and total steam output. Reduction of steam output will occur by lowering

the water level.

Mitigation of lime/scale:

Steam generated in an electrode cylinder is pure water (H2O). This means that all the ions from the supply water remain in the tank in the form of scale.

The resulting build-up can be mitigated by flushing the cylinder periodically, however, over time the scale will accumulate to a point where the electrodes

are coated and unable to generate the capacity required. The plastic tank will then have to be removed and discarded and, a new tank acquired and installed.

Resistive electric humidifiers use electric, self-cleaning, immersion heating elements to raise the temperature of the water to

the boiling point within a permanent stainless steel evaporation chamber. Each of these immersion heaters has a specific power rating (KW) at a specific voltage.

This radiant heating will raise the temperature of the water within the evaporation chamber to the boiling point, independent of the ion content of the water,

thus permitting equal performance in purified (de-ionized or reverse osmosis) water or potable water. The capacity of steam generated is controlled by switching

power over time to the resistive elements. This is accomplished in most cases with SSRs (solid state relays) with integrated zero voltage crossing (SCR control).

Mitigation of lime/scale: In potable water installations, the build-up of ions (scale) within the tank is mitigated with frequent flush cycles.

Although the output of the humidifier will not be affected by the build-up of scale, the evaporation chamber will have to be removed and cleaned periodically.

In pure water applications, these drain cycles may be greatly reduced or eliminated depending on the purity of the water, effectively increasing the efficiency

of the humidifier and reducing the service required.

In next month’s article, we will look at the total cost of ownership and the pros and cons of each on a per-application-basis.